What's the Difference between Fiberboard and Particleboard?

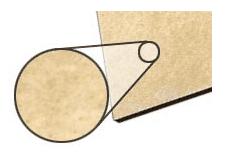

Medium-Density Fiberboard

Medium-density fiberboard (MDF) is an engineered wood product formed by breaking down softwood into wood fibers, often in a defibrator, combining it with wax and a resin binder, and forming panels by applying high temperature and pressure. It is made up of separated fibers (not wood veneers), but can be used as a building material similar in application to plywood. It is much more dense than normal particle board.

MDF has many advantages over plank wood, particleboard or high density fiberboard. It's very smooth because the wood fibers used in its manufacture are uniform and fine. This makes it have low "tear out," which means that when sawed, the end has a smooth cut instead of a jagged edge. This also means that a coat of primer and a couple of coats of paint take well, leaving an attractive, finished surface unlike other composite wood products. MDF also has a mild reaction to moisture, meaning it won't warp or swell in high-humidity applications like a bathroom cabinet.

Builders often use MDF in furniture, shelving, laminate flooring, decorative molding and doors. They value MDF for its heat and sound insular qualities. Also, it can be nailed, glued, screwed, stapled or attached with dowels, making it as resourceful as plank wood. Usually, people working with MDF use a carbide saw fitted with a vacuum to reduce the amount of airborne dust. Since MDF is strengthened with resin containing formaldehyde, those at exposure try to reduce their risk of inhalation, or use special MDF with lower formaldehyde levels.

Reconstituted, engineered wood products like MDF are often covered in a veneer or laminate. These thin layers of vinyl or real wood disguise the MDF, especially along visible edges. Some people prefer using MDF over regular lumber because it has a lower impact on the environment. MDF is solely made from waste products, the leftover scraps that would otherwise be dumped in a landfill. This attraction has helped it gain popularity among homeowners.

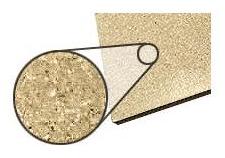

Particleboard

Particleboard, (or chipboard in the UK, Australia and some other countries) is an engineered wood product manufactured from wood particles, such as wood chips, sawmill shavings, or even saw dust, and a synthetic resin or other suitable binder, which is pressed and extruded.

Particleboard is a type of fiberboard, but it is comprised of bigger pieces of wood than medium-density fiberboard and hardboard.

Particleboard is less expensive, denser and more uniform than the usual wood and plywood and is substituted for them when appearance and durability are less important than cost. However, particleboard can be made more attractive by painting or the use of wood veneers that are glued onto surfaces that will be visible. Though it is denser than conventional wood, it is the lightest and weakest type of fiberboard, except for insulation board. Medium-density fiberboard and hardboard, also called high-density fiberboard, are stronger and denser than particleboard.

A major disadvantage of particleboard is that it is very prone to expansion and discoloration due to moisture, particularly when it is not covered with paint or another sealer. Therefore, it is rarely used outdoors or places that have high levels of moisture, with the exception of some bathrooms, kitchens and laundries, where it is commonly used as an underlayment beneath a continuous sheet of vinyl floor covering.